-40%

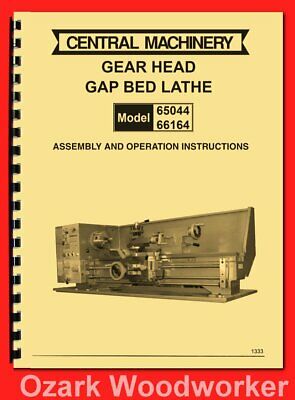

9x20 Metal Lathe Parts Manual-Jet,Enco,Grizzly,MSC,Asian 0776

$ 10.56

- Description

- Size Guide

Description

Untitled DocumentFree, Fast Shipping Every Business Day!

See All Categories

How-to Books

Lathe Practices Series

Lathe Operations

Milling Operations

Grinding Operations

Metalworking

Woodworking

Brands

JET Tools/Asian

Asian

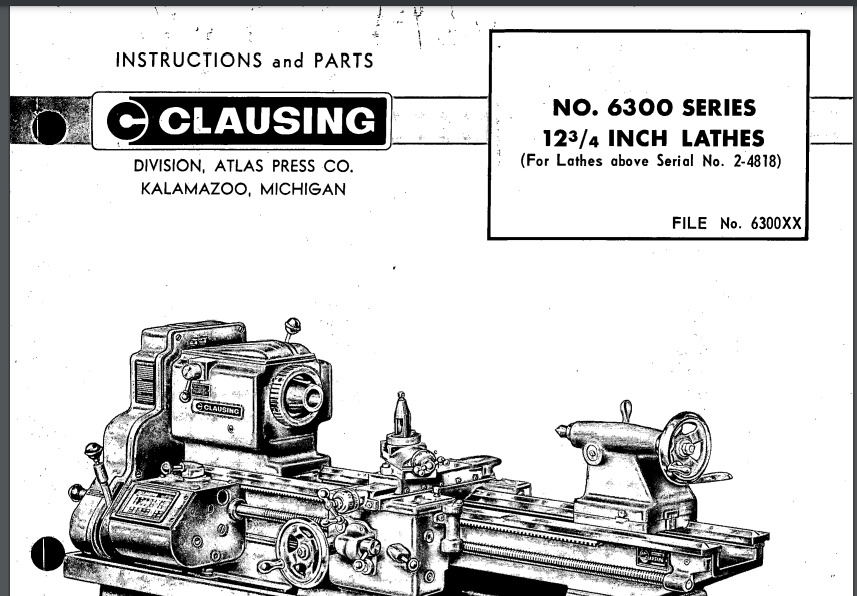

9" x 20" Metal Lathe

Instructions and Parts Manual

Manual Description:

Number of Pages: 31

This is a reproduction of an original Asian 9" x 20" Metal Lathe Instructions and Parts Manual. This machine is manufactured in Asia and has been sold under many different names including: JET, Grizzly, Enco, MSC, etc... This manual contains information on set up, lubrication, maintenance, and controls as well as a complete parts list and exploded views and adjustments.

Picture:

Specifications:

Capacities

Compound & Carriage

Swing Over Bed:

9"

Tool post Type:

4-Wav

Swing Over Cross Slide:

5 5/16"

Maximum Tool Size:

1/2" x 1/2"

Distance Between Centers:

20"

Maximum Compound Slide Travel:

1 7/8"

Headstock

Maximum Cross Slide Travel:

5"

Hole Through Spindle:

7/8”

Tailstock

Spindle Nose (Threading Size Varies):

PTESE 11/2" x 8 T.P.I.

Tailstock Spindle Travel.

1 9/16"

Taper in Spindle Nose:

SPECS MT 3

Diameter of Tailstock Spindle:

1 1/16"

Number of Spindle Speeds:

of Spindle Speeds (RPM):

6 Range

130-2,000

Taper in Tailstock Spindle:

MT 2

Gear Box

Miscellaneous

Number of Longitudinal Feeds:

18

Length of Bed:

32"

Range of Longitudinal Feeds (inch/rev.

.005”.011”

Width Bed:

41/2"

Range of Inch Threads:

8-56 T.P.I.

Overall Dimensions:

371/2" Lx 19 3/4'' Wx 15 3/4'' H

Range of Metric Threads:

.05-3.0 mm

Main Motor.

% HP, 1 Ph, 60 Hz

Leadscrew:

9/16" x 16 T.P.I.

115V or 230V

Contents:

Specifications..............................................................4

Standard Equipment....................................................4

Technical data.............................................................4

Set Up and preparation for operation..........................4

General Description....................................................5

Lathe Bed..................................................................5

Headstock..................................................................5

Carriage.....................................................................6

Apron........................................................................6

Tailstock.....................................................................7

Leadscrew..................................................................7

Gear Box....................................................................7

Drive and Electrical Equipment....................................7

Controls.....................................................................8

Working with the BD-920...........................................9

Tool Set Up................................................................9

Manual Turning...........................................................9

Longitudinal Turning with Auto-Feed...........................9

Taper Turning using Tailstock Set-over......................10

Taper Turning by Setting the Top Slide......................10

Turning between centers............................................10

Thread Cutting...........................................................11

Example of Gear Set up to cut 10 T.P.I......................11

Slip Clutch.................................................................11

Thread Cutting Tables................................................11

Lathe Accessories.....................................................12

Universal Lathe Chuck, 3 or 4 jaw design.................12

4-Jaw Independent Chuck.........................................12

Drill Chuck...............................................................12

Morse Taper Arbor..................................................12

Live Center...............................................................12

Steady Rest..............................................................13

Follow Rest..............................................................13

Setting the Steady Rest..............................................13

4-Way Tool Post......................................................14

Gear Change.............................................................14

Bearing and Slide Adjustment....................................15

Adjustment of Main Spindle Bearings........................15

Adjustment of Cross and Top Slides..........................15

Adjustment of Feed Screw End Float........................15

Feed Screw Backlash Adjustment.............................15

Cross Slide Screw....................................................15

Compound Slide Spindle Backlash Adjustment..........16

Adjustment of Half-Nut Guide...................................16

Adjustment of Lead Screw Backlash.........................16

Replacing the Shear Pin in the Leadscrew..................16

Replacing the V-belt..................................................17

Lubrication schedule..................................................18

Wiring diagram..........................................................19

Parts Breakdown.................................................20-31

Overview:

I have collected this information for many years and have found the information they contain to be priceless in using and setting up the machines properly. I believe this manual will be a valuable resource of knowledge that will provide a lot of helpful information that is often hard to find. My manuals are not photocopies. I maintain a high standard of quality in my reproductions. Most of the manuals I reproduce look better than their originals. I have professionally digitally edited every page, and removed stains, wrinkles and handwriting. All of the manuals are printed on thick white paper to withstand shop wear and tear.

Click here to see other work I do, and pictures of my shop

.

From our shop to yours.

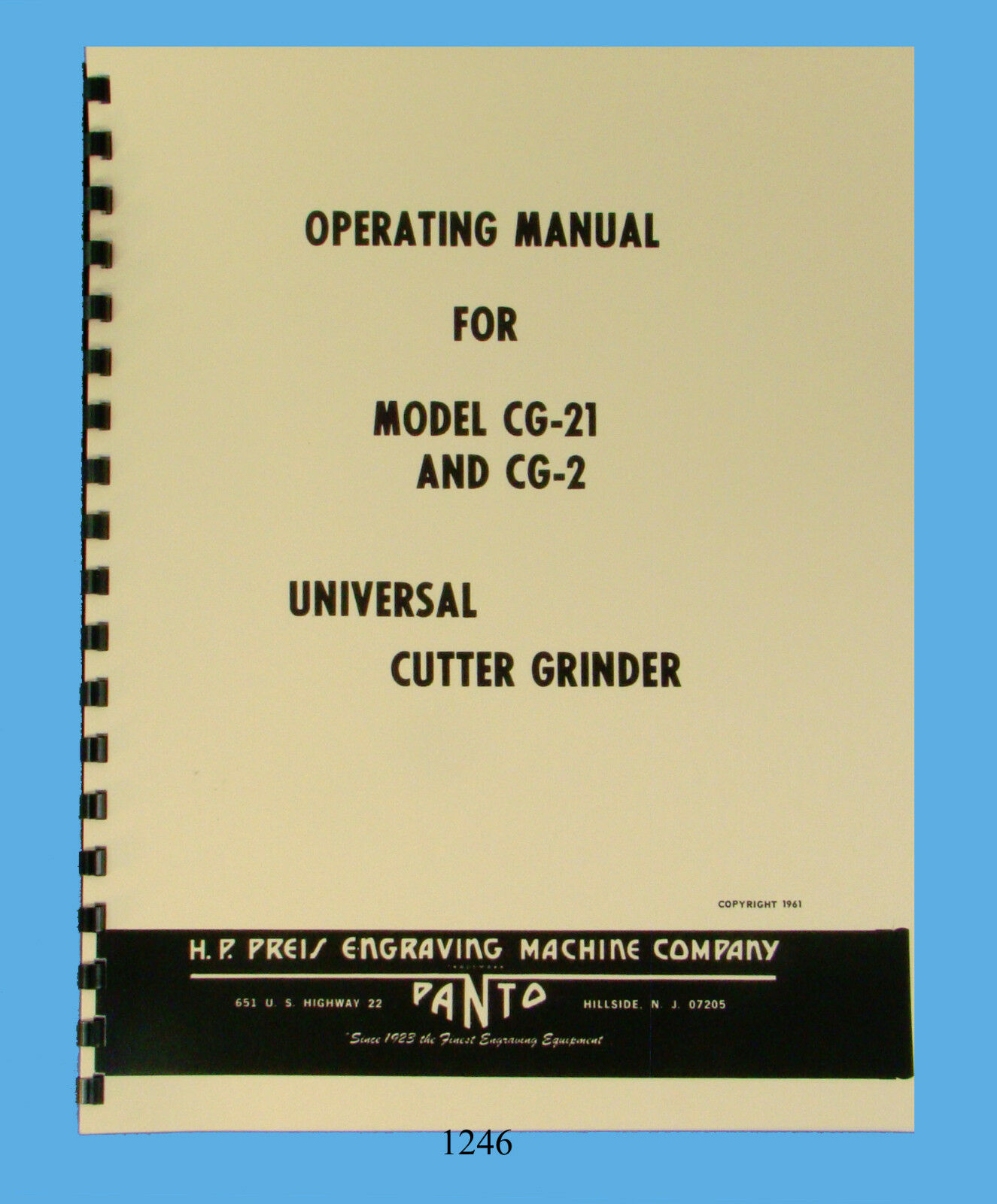

We get this.

But you get this!

Why settle for anything less?

Check out my

other manuals

.

Shipping:

Returns:

,

Be sure to add me to your

favorites list

, and

check out our

other items

!

I may have more than one manual that covers your machine,

and I am adding new manuals all the time.

I do not carry additional parts for machinery, except for what is listed.

Powered by

eBay Turbo Lister

The free listing tool. List your items fast and easy and manage your active items.